![]()

Did you know that Samuel Franklin Cody was the first person to pilot a powered and sustained flight in Britain in 1908? since then aircraft has come a long way. An aerospace engineer primarily works with aircraft, spacecraft, satellites and missiles. They make sure aircraft functions safely and efficiently.

Top 5 skills:

- Technical expertise

- Attention to detail

- Mathematical and analytical thinking

- Problem-solving

- Some creative thinking

Video

Diary of an Aerospace engineer

Welcome to a year in the life of an Aerospace Engineer. Each month our engineer has made an entry for you to give you a flavour of what it’s like doing their job.

ONE

I am currently working on a research project and the team has been putting in long hours. Aerospace engineers normally work 37 to 40 hours a week. Sometimes we work late into the night when we have a project deadline to meet but mostly I work pretty regular hours Monday to Friday.

I have worked with a private aerospace research company here in the Midlands since I graduated from the University twelve years ago. After graduating I studied for my master’s degree while employed, and that was hard work with a young family to support. It has been worth it though.

TWO

Aerospace engineering involves working with vehicles that are designed to operate outside of the earth’s atmosphere. Literally, it IS rocket science! At school I loved maths and science but it was my love of the big screen that drew me to the aerospace industry. Daydreaming about building a rocket-like the ones you see in the movies is one thing but working in the field is another.

No, I don’t design spaceships but I work with those same principles every day. Most of my time is spent problem-solving on small parts of the puzzle that makes up an aircraft. It is challenging and frustrating at times.

THREE

Aerospace engineers work with aerospace manufacturers and airline operators. Other employers include the armed forces, government departments and agencies, and regulatory authorities, such as the Civil Aviation Authority (CAA) and airports. There are clusters of aerospace companies around the UK, notably in the Midlands, western and north-western England, Northern Ireland and eastern England. Their skills are also in demand by manufacturers of other vehicles such as hovercraft, cars and trains.

I have been lucky to find work here in the area of research and design. We work in teams to see projects from concept through to construction so that there is continuity throughout the project. We work with other specialists like material engineers and Computer-Aided Designers to develop solutions for aeronautical problems.

FOUR

I have a clean, quiet laboratory and office area in the research centre, but sometimes I get the chance to visit the production or testing areas. This week we travelled to the airfield where one of our team projects has reached the testing stage. It is important to get out in the field for several reasons.

I like to see our work come to life, it keeps you inspired and excited about the project. It also gives us a chance to talk to the people involved in the building and testing of the designs we create. This gives us feedback about our work and often sparks a new idea too.

FIVE

At first glance, aerospace engineering may seem like a narrow field, but there are numerous specialities within the field. In fact, aerospace engineering has the seventh-highest employment distribution of all fields of engineering.

Aerospace engineers can specialize in guidance systems, structural design, manufacturing, control and navigation or communications systems. Aerospace engineers can also specialize in a specific type of air or spacecraft, and often become experts in certain areas of physics like thermodynamics, aerodynamics, or acoustics.

I work across a range of tasks as I am employed by a smaller research facility. My area of speciality is in aerodynamics and I have done extensive further study in this field.

SIX

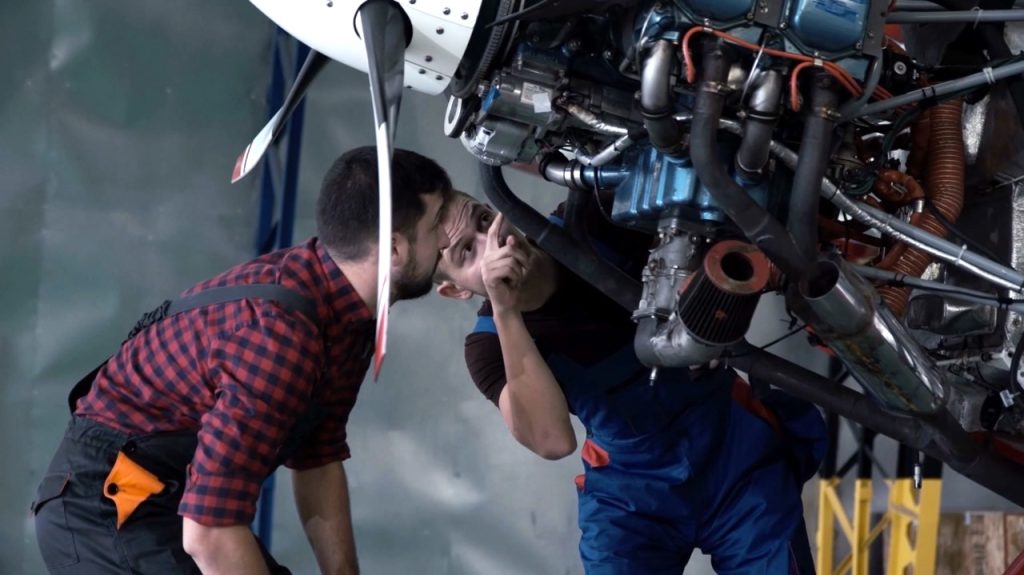

We headed out into the field again yesterday to see one of our client’s aircraft being tested. I am always keen to keep up to date with new developments and technology and I read widely outside of my working hours. Spending time at the airfield and working with the pilots and mechanics is vital for me to stay in touch with what is happening in practice. It’s easy to forget that what we design and draw has to work at the end of the day!

As an aerodynamics specialist, I work closely with our CAD team who turn my drawings into computer designs. I have a meeting tomorrow with the CAD team for our new project specifications so I will need to put in some time today to make sure I am ready.

SEVEN

It was an exciting day with a meeting this morning with the CAD team and then off-site again in the afternoon with one of our material manufacturers. On the new project team, I have been working on the materials and structures of the client’s aircraft. This involves investigating and testing new and existing materials for airframes and components.

We have been experimenting with new materials and the initial results from our airfield testing look very promising. I met with the manufacturer to discuss our testing results and to look at ways that we might fine-tune the production further.

EIGHT

Another early start is on the cards for tomorrow as we have more testing and the wind tunnel is only available at 8 am! We use the wind tunnel a lot for testing rather than waiting to test components or materials on a completed aircraft. Tomorrow we are testing some changes to the material being used on a small section of the airframe so we can do this in miniature in the wind tunnel quite easily.

Aircraft are expensive and we also have to factor in the number of people needed to test a competitive craft out on the airfield. It all adds up to more cost and time for the client. All our materials will have to be tested in the field later in the project as it is impossible to simulate all the climatic and wind conditions an aircraft will encounter n the real world.

NINE

Sometimes it is hard to stay focused. I have had a tough week at work and I can’t wait for the weekend. As an engineer, I work on only a small part of any given project. It is exciting to go out to the airfield and see your work in action but most of the time I spend my days in the lab or my office at the PC. Some of our new material tests haven’t gone as well this week and I’m having trouble figuring out why.

Being able to solve complex problems is a big part of what I do but sometimes it is hard to know what has gone wrong. I am only responsible for a small part of the project and that can be frustrating as it can feel like you don’t know what is going on.

TEN

The UK aerospace industry employs over 250,000 people and has an annual turnover of more than £18 billion. More than 85,000 people currently work in engineering-related occupations in the aerospace industry. There is currently a shortage of suitably qualified aerospace engineers.

Any practical experience in the field is helpful, as entry into the industry is highly competitive. An aeronautical engineering degree is the most likely route into a career. Apprenticeships are available. Mike, one of the members of my team, trained for a technician-level job straight from school with good GCSE grades in English, maths and physics.

Experienced engineers with the level of experience I have can earn around £40,000 or more, depending on their professional status. Rates of pay vary of course, depending on the employer and the location. As a graduate aerospace engineer, you would usually earn between £20,000 and £25,000 a year.

ELEVEN

I have spent a lot of time this week in the office preparing reports on the different materials trials we have been doing. I need to be able to communicate my ideas, verbally and in writing to other members of my team and to our clients. We work in a multidisciplinary team, which means that we are working with people who have different skills and specialities.

My role is just one small part of the total project. I do get a great feeling of satisfaction when we solve a problem. This isn’t a job where you get a lot of accolades and recognition outside of your team or workplace though.

Written reports contain all of our test data and more detail about the problem-solving we have done. I use diagrams, drawings and graphs to make my point clear.

TWELVE

Aerospace engineers are expected to undertake continuing professional development. This can include attending courses, meetings, workshops and seminars. The company that I work for encourages us to take on further education in the areas we are interested in.

Last year I completed a course in risk assessment and management. I did this study in my own time in an online and workshop format. As well as expanding my skills and knowledge I met other people working in the industry. It is important to build up a network of contacts. Your network contacts can help you get in touch with other specialists who might be able to help solve a problem in a project.

Working on projects involves teams of people, and aerospace engineers work with different types of engineers, designers and the manufacturer, as well as pilots and users of the aircraft.

I look forward to an exciting future!